Our factory shown that:

- Un plasticized u P.V.0 pipes are strong but light.

- Its specific gravity being approximately one- fifth that cast iron.

- As a result, these pipes are more easily handled than their metal counterparts.

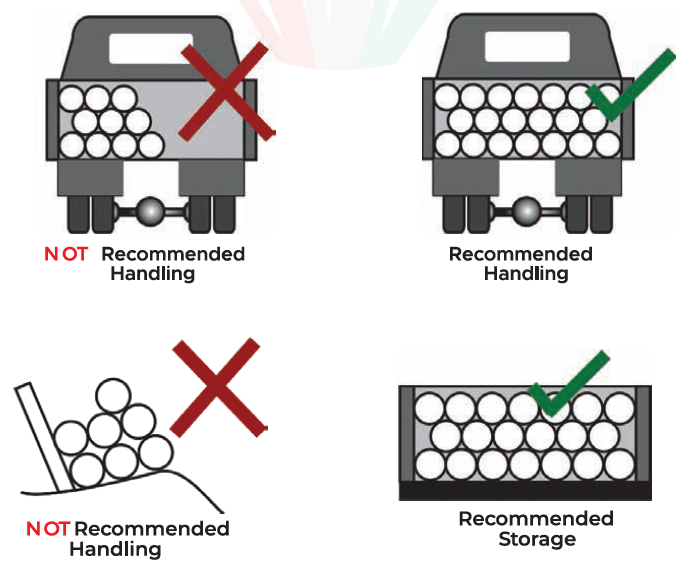

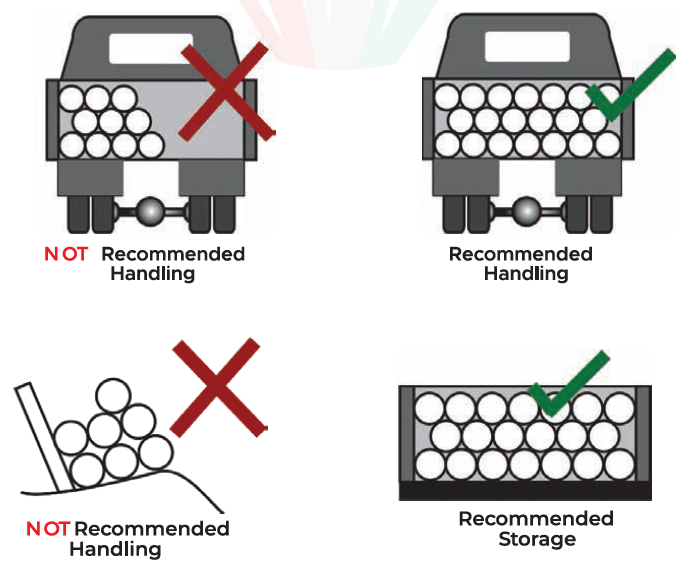

- Reasonable care, however should be exercised at all times, and when of loading, pipes should be lowered, not dropped to the ground.

- Pipe should be given adequate support at all times.

- Pipes should not be stacked in large piles especially in warm temperature conditions, as the lower layers may distort: resulting in difficulties when joining and for pipe alignment.

- Any pipe with ends prepared for joining (socket and spigot joints, RR joints, etc.) should be stacked in layers with the socket, placed at alternate ends of the stack and with sockets protruding to avoid lop-sided stacks and the Imparting of permanent set to pipes.

- Particularly in the case of Ring pipe, rubber rings should not be exposed to solar radiation for any length of time if they are not coated.

- It is recommended to stock them in a cool and shady place.

- Rubber rings should not come in touch with chemicals, grease, oil and to be stored for too long a time.

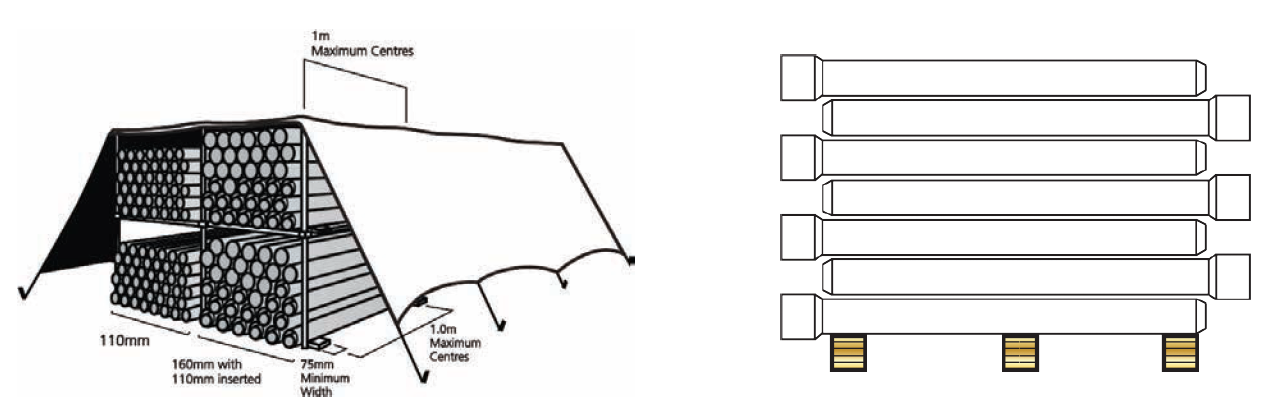

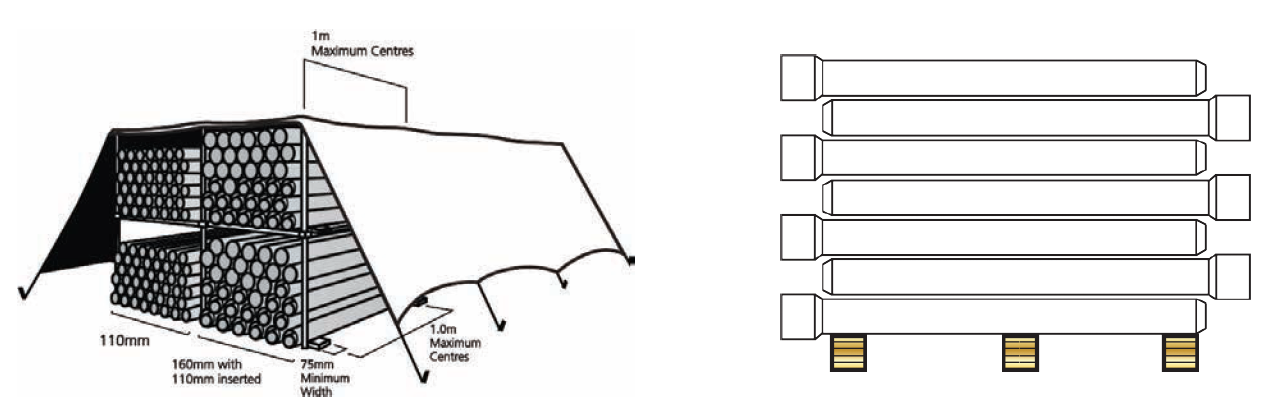

- For long-term storage, pipe racks should provide continuous support, but if this is not possible, timber of at least 75 mm bearing width at spacing not greater than 1 m centers for pipe sizes 150 mm and above, should be placed beneath the pipes and at 2m centers at the side, if the stacks are rectangular.

- These spacing apply to pipe size 160 mm and above.

- Closer supports will be required for sizes below 160 mm.

- In such pipe racks, pipes may be stored not more than seven layers or 1.5 m high. whichever is the lesser, but if different classes of pipe are kept in the same racks, then the thickest classes must always be at the bottom.

Non-Exposure to direct sunlight

- For temporary storage in the field, where racks are not provided, the ground should be level and free room coarse stones.

- Pipes stored thus should not exceed three layers high and should be staked to prevent movement.

- Stack heights should be reduced i pipes are nested; i. e. pipes stored inside pipes o larger diameters.

- Reductions in height should be proportional to the weight of the nested pipe compared to the weight of the pipes normally contained in such stowage's.

- Since the soundness of any joint depend on the condition of the spigot and the socket, special care must be taken in transit, handling and storage to avoid damage to the ends.

- When loading pipes on the vehicles, care must be taken to avoid their coming into contact with any sharp corners such as cope irons, loose nail-heads, etc., as pipes may be damaged by being rubbed against these during transit whilst in transit pipes shall be well secured over their entire length and not allowed to project unsecured over the tailboard of the lorry.

- Pipes may be off loaded from lorries and or by rolling them gently down timbers, care being taken to ensure that pipes do not fall one upon another nor on any hard or uneven surfaces.

- Fork-lift trucks will have to be used for bundles and large unit loads.

Excavation

- The width of the trench excavation should be kept to a minimum, allowing just sufficient working area for jointing and initial compaction around the pipe. For most purposes, a trench 300mm wider than the diameter of the pipe allows enough room for jointing.

- It is important that the trench is not excavated too far in advance of the pipe laying operation, especially in situations where the trench walls are unstable

BEDDING

- The quality of the bedding material and its compaction, together with the nature of the undisturbed material of the trench walls are all relevant to the ultimate performance of Du roflo and Ultraflo pressure pipes once installed.

- The trench bed must be free from all stones or sharp projections which are likely to cause damage to the pipe.

- The bottom of the trench should be backslid to a depth of 100mm, with selected bedding material such as free draining coarse sand, gravel or soil of a friable nature.

- The size of soil particles in the bedding material should not exceed 20mm.

- The bedding, onto which the pipe is laid, should be thoroughly compacted to the specified density.

- Reference should be made to SANS 2001 for bedding specifications

ANCHORING

- When an internal hydrostatic pressure is applied to the pipe, unbalanced forces develop at all changes of size and direction in a pipeline.

- Thrust blocks prevent the movement of fittings and must be placed at all changes of direction, valves, stop ends and reducers. Concrete thrust blocks are most commonly used at all anchor points.

- The dimensions of the thrust blocks must be calculated to suit the pipe diameter, pressure and the load bearing capacity of the soil.