Solvent cement/glue jointing system

This method, otherwise known as a Solvent Weld, is the most popular and requires a low skill capability. PVC 'solvent cement' or 'glue' is in essence the chemical mixture that when applied to the mating surfaces of the PVC pipe, fitting or valve connections, welds them together by means of a chemical reaction creating what is technically known as an 'homogenous bond' i.e. the two separate surfaces are now chemically fused to become one.

CORRECT JOINING PROCEDURE:

- Cut the pipe square and deburr the spigot.

- Mark the socket depth to the spigot end.

- Clean dry and degrease the two jointing surfaces.

- Check the fit before making any cuts or applying any glue

- Apply priming fluid to the socket and the spigot ends.

- Apply an even coat of solvent cement to both the socket and spigot ends.

- Insert the spigot the full market depth of the socket and HOLD for a minimum of 30 seconds.

- Clean off any surplus solvent cement.

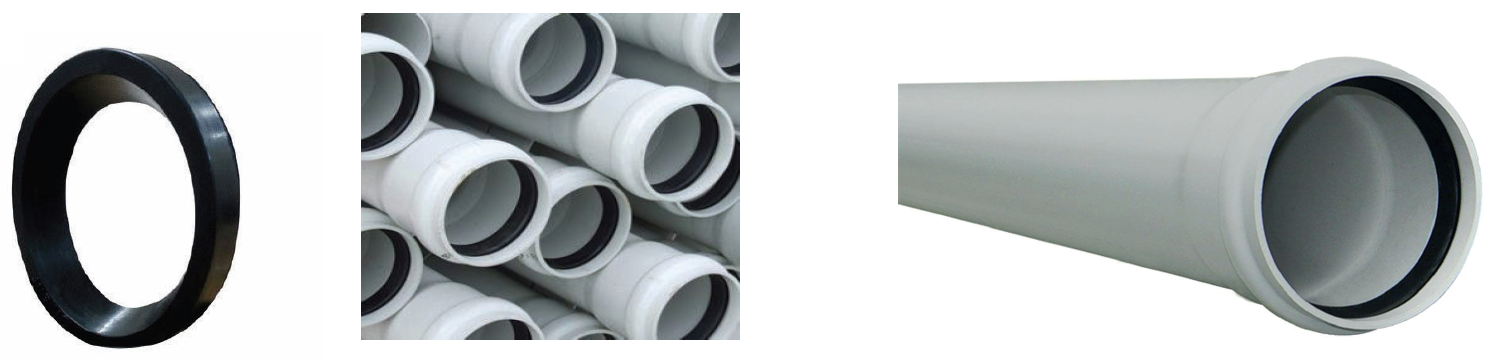

Rubber ring joining

Rubber ring joints provide a fluid seal by compressing a rubber ring housed in the socket of a pipe or fitting when the spigot is passed into the socket. the correct jointing ring are supplied with the pipe or fitting