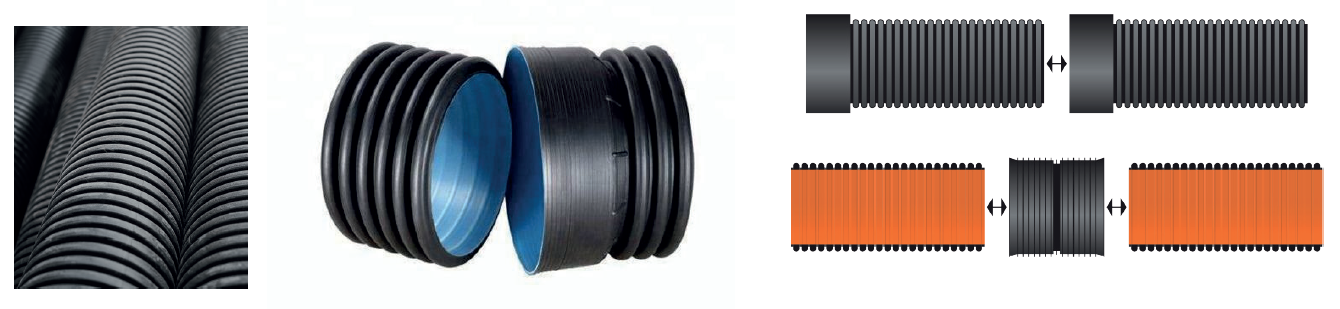

NEWPRO HDPE corrugated pipes have one side socket (Female) and other side pipe end (male). For connection, the pipe end and the inside socket (female) must be cleaned and then the appropriate gasket should be placed on the pipe end and then lubricated with soap or other materials. It is imperative that the joint be assembled properly to ensure that the product performs to expectations. The steps that must be followed to obtain a quality joint are provided below.

- Lowerpipe into trench by hand, or use nylon straps and excavating equipment.

- Begin by inspecting the socket and remove any foreign matter.

- Use a clean rag or brush to lubricate bell of pipe lubricant.

- Clean spigot end of pipe. Remove protective wrap from gasket.

- Using clean rag or brush, lubricate exposed gasket with pipe lubricant.

- Do not allow lubricated section to touch dirt or backf ill. Foreign matter could adhere to surface and compromise joint integrity.

- Place spigot into bell and align.

- Note: Always push spigot end into bell, not bell end onto spigot.

- Assemble joint using one of the following methods. For smaller diameters, pipe may be joined manually.

- For all methods, ensure bell and spigot are adequately "homed" for proper installation and tight joining seal.

- If no homing mark is present, measure the depth of the socket and use a crayon or other material to place a homing mark on appropriate corrugation of the spigot end.

BAR & BLOCK METHOD

- Place installation stub into socket end of pipe.

- Place wooden block horizonta lly across end of installation stub.

- With a bar, push against wooden block untilpipe is fully inserted into bell.

BACKHOE METHOD

- Place installation stub into bellend of pipe.

- Place wooden block horizonta lly across installation stub.

- Carefully push back of backhoe bucket against block until pipe is fully inserted into bell.

BACKHOE AND SLING METHOD

- Wrap nylon sling around pipe. Pipe 36" (900mm) or larger should be picked up at two points approximately 10' (3m) apart.

- Hook other end of nylon sling to backhoe bucket.

- Operator should carefully push strap tight toward bell of downstream pipe until spigot is fully inserted into bell.

- Ensure pipe slides squarely into bell to avoid misalignment.

- Keep pipelevel.