High Density Polyethylene pipes and f ittings are connected to each other by ButtWelding, Electrofusion Welding or mechanical fittings. Pipes made from materials other than polyethylene can be connected by compression fittings, flanges or other suitable adapters made for the purpose.

Currently, two methods are used in joining H ODPE pipes:

- Electrofusion (EF) welding

- Butt Welding

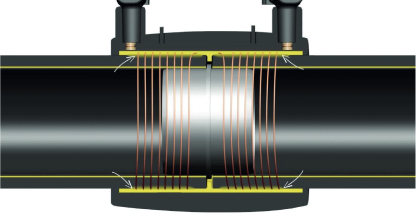

ELECTROFUSION WELDING

In the electrofusion welding process, welding is done with heating resistors inside the fusion fitting. Once the pipes are placed in the electro fusion fittings, the ends of the welding machine are connected toltthe resistors of the electro fusion f itting and heating them. So, HDPE pipe will be connected with the electrofusion fitting. Electrofusion welding is more advantageous when it is necessary to weld in where welding machine can not fit.

|

|

BUTT WELDING

The Butt welding method is the most common welding method currently used for joining HdPE pipes and fittings.The pipe joining method is a process in which the two ends of the pipes to be heated and welded by using a butt welding machine and the both ends are pushed toward each other by pressure under a certain temperature. In terms of welding cost, the butt welding is cheaper than the electrofusion welding.

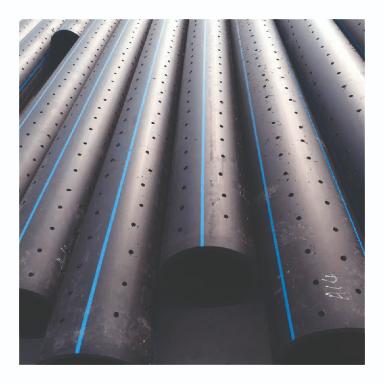

HDPE PERFORATED PIPES

A perforated pipe is designed with small slots or holes to allow water to exit or enter easily. This type of pipe is frequently used for underground drainage systems and other uses due to its ability to absorb and drain water.

WE ARE PRODUCING 3 TYPE OF PERFORATED PIPES ACCORDING TO QCS 2014

>> Half perforated

>> 3% perforated

>> Fully perforated